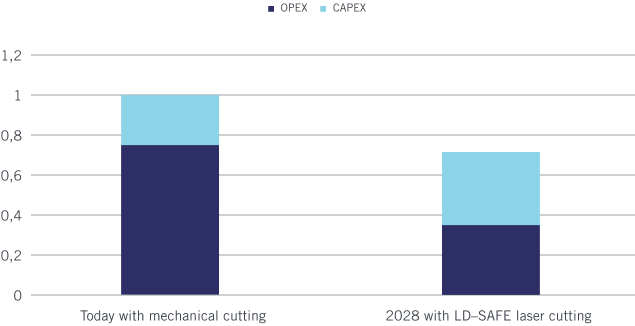

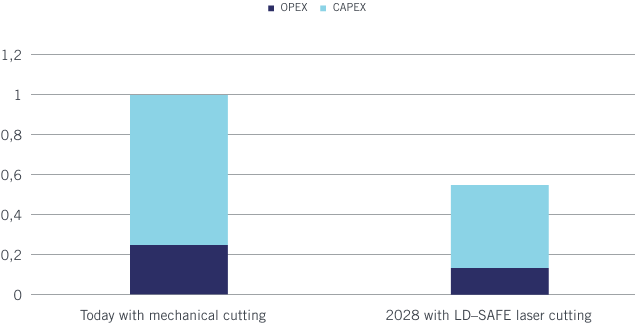

European End Users would save significant costs on the long run by using the LD-SAFE technology

It is actually on the basis of ensuring safety and protecting the workers and the environment that the technology application proposed by LD-SAFE could contribute to reducing the time needed to dismantle power nuclear reactors. Indeed, as reflected in the projects KPIs, the reliability (KPI 4), absence of maintenance by workers in controlled area (KPI 5) and ability of laser cutting to proceed at fast cutting speed while guaranteeing safety (KPI 6) while minimizing the secondary waste generated (KPI 2) are all safety related benefits that contribute to decreasing the dismantling time.

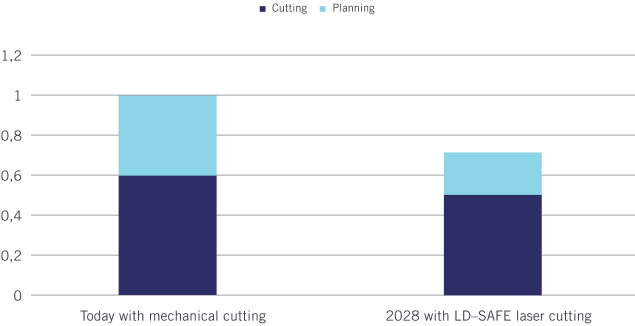

The figure below illustrates the ambition of the project to demonstrate that using the laser cutting technology for the segmentation of PWR internals could allow reducing the time for such project by 30% compared to what is currently achieved using mechanical cutting (KPI 7). It is estimated that a part of project time will be saved during the planning phase, thanks to the lower quantity of tools (versatility of laser cutting – KPI 3) and the simplicity of implementation (modularity of laser cutting), and that a large part of project time will be saved during the works (speed of laser cutting – KPI 1).